Making a Good Connection

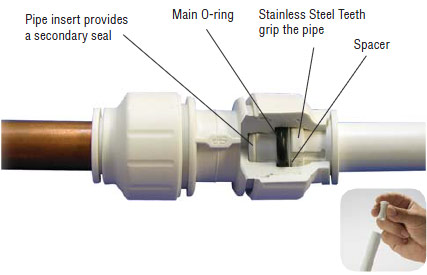

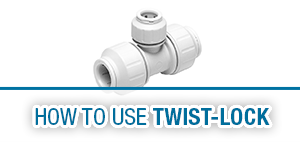

Like John Guest Standard Fittings, Twist and Lock Fittings have a collet with stainless steel teeth that grip the pipe when fully inserted, and an O-ring to provide a permanent leak-proof seal. The additional benefit of the Twist and Lock fitting is that a twist of the screw-cap gives greater compression on the O-ring seal and locks the pipe in place for greater security.

Step 1 – Prepare the Pipe

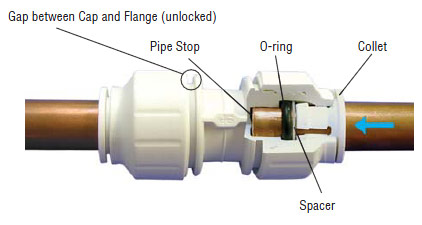

To prevent damage to the O-ring remove all burrs and sharp edges. When using Speedfit Pipe, we recommend the use of a Pipe Insert. The insert should only be used with Speedfit Pipe.

Step 3 – Push Up to Tube Stop

The fitting should be in the ‘unlocked’ position. This is shown by a small gap between the screw-cap and the body flange. Push the pipe into the fitting and up to the pipe stop.

Step 4 – Pull To Check if Secure

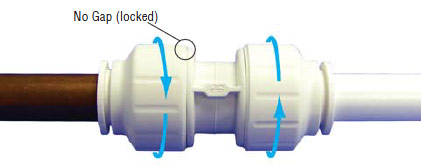

Twist the screw-cap until it touches the body flange. This locks the pipe into position and increases the o-ring seal around the pipe.

Pull to check that it is secure. It is good practice to test the system prior to leaving the site or before use. The recommended test procedure is shown in the John Guest Technical Checklist.

Disconnecting

Ensure that the system is depressurized.

Be sure to twist the screw-cap back to the unlock position. Push the collet square against the face of the fitting by using fingers. With the collet held in this position the pipe can be removed.

The fitting can be used again without the need for replacement parts. (Ensure the fitting is clean before every use).

What Not To Do

- Do not use damaged or scored pipe.

- Do not use a hacksaw to cut the pipe.

- Do not leave burrs on the end of the pipe.

- Do not forget to push the pipe fully into the fitting, past both the collet (gripper) and the O-ring.

- Do not insert fingers into the fitting as the stainless steel teeth may cause injury.

Remember to pressure test the completed installation according to the recommendations in the John Guest Technical Checklist.

A boil-water advisory or boil-water order is a public health advisory or directive given by government or health authorities to consumers when a community’s drinking water is, or could be, contaminated by pathogens.

Learn how to make an emergency water filter for disaster situations out of some common items.

This method does work and can keep you heathly if clean potable water or a manufactured water filter system are unobtainable.

The Hydrologic Cycle (also called the Water Cycle) is the continuous movement of water in the air, on the surface of and below the Earth.

This cycle is the exchange of energy which influences climate. When water condenses, it releases energy and warms the environment.

90% of the garbage floating in the Earth’s oceans is plastic and less than 5% of all plastic is recycled.

The patch mostly consists of pelagic plastics, formed from plastic bags, plastic water bottles, bottle caps and styrofoam.

Hydraulic fracturing (sometimes referred to as fracking or hydrofracking) is a relatively new form of natural gas extraction.

The fluids used in the fracking process flow back to the surface, often entering the water table or polluting the drilling area, and sometimes improper disposal of waste water from the wells.

Chlorine has long been recognized as an oxidative agent, meaning that it not only kills the germs in the water supply; it will damage any living tissue with which it comes in contact. And your skin, like the rest of your organs, is living tissue. But that’s not the only problem.

Since the discovery of its health benefits in the mid-1940’s, fluoride is often added to the public water supplies of industrialized countries in order to reduce the populations tooth decay, which is especially effective in low income communities, where good dental hygiene may be too costly.

Chromium-6 was found in the drinking water supply of the southern California town of Hinkley and brought to national attention by Erin Brockovich.

The EPA is reviewing effects of Chromium-6 after a recent report brought to light dangerous levels in a number of major US cities.

Giardia is a flagellated protozoan parasite that colonizes and reproduces in the small intestines of humans and other animals, which can cause giardiasis.

Symptoms of Giardiasis usually show after 3 to 4 days, and include gastrointestinal and constitutional problems.

Cryptosporidiosis is a disease caused by the parasite Cryptosporidium parvum.

Since a outbreak in 1993 in Wisconson, new attention has been focused on determining and reducing the risk for Cryptosporidiosis from community and municipal water supplies.

What is ultraviolet light? Do I need to filter the water before the UV process? How exactly can light kill organisms?

Visit our ‘How Ultraviolet Purification Works‘ guide to find out how it works.

The typical water softener is a mechanical appliance that’s plumbed into your home’s water supply system. All water softeners use the same operating principle: They trade the minerals for something else, in most cases sodium. The process is called ion exchange. More…

Need to filter water but not sure about the differences between or applications of our systems?

Use our Water Filter Systems Guide to find out which system is best for your filtration needs.

The size of your water softener depeneds on the total grain per day that need to be removed.

This is determined by the number of people in your household, grain per gallon (GPG) hardness and the amount of Iron present in the water.

A micron is a unit of measurement for how small of particles a filter will catch. The lower the micron size, the tinier the ‘holes’ in the filter cartridge are that allows water to pass through, ranging from 0.1 absolute to 150 microns.

Use our Pore Size Efficiency Guide to find out what micron size to use.

Pleated sediment cartridges remove dirt, rust and sediment from water while providing an increased surface area and longer life. Pleated filters down to 5 microns are washable and reusable.

Use our Pleated Sediment Cartridge Comparison to find the filter cartridge you need.

Aquariums need three types of filtration to maintain a healthy environment for freshwater, saltwater or amphibian aquariums (sediment filtration, carbon filtration, and removal of biological contaminants).

When traveling around the state or the country in a RV you might not always know where you will be getting the water from or what might be in it. Water that is stored in a RV holding tank will not stay potable for long and can become a breeding ground for algae and bacteria.

Chemicals added to public water supplies, like chlorine, can be harmful to the living cells of plants.

When brewing beer with tap or bottled water, chlorine and chloramine present in the water can combine with malt phenols in the wort to create a compound called chlorophenol, which can give the beer a medicinal taste.

View our Filtered Water for Home Beer Brewing guide.

Bottled water requires a lot of resources to manufacture and ship, and costs a lot more than reverse osmosis water.

Use our Bottled Water Cost Calculator to find out how much of an impact you have on the environment.