What is Reverse Osmosis?

Source: WikipediaReverse osmosis (RO) is a membrane-technology filtration method that removes many types of large molecules and ions from solutions by applying pressure to the solution when it is on one side of a selective membrane. The result is that the solute is retained on the pressurized side of the membrane and the pure solvent is allowed to pass to the other side.

How Does Reverse Osmosis Work?

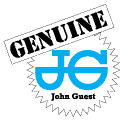

In the normal osmosis process, the solvent naturally moves from an area of low solute concentration (High Water Potential), through a membrane, to an area of high solute concentration (Low Water Potential). The movement of a pure solvent to equalize solute concentrations on each side of a membrane generates osmotic pressure. Applying an external pressure to reverse the natural flow of pure solvent, thus, is reverse osmosis. The process is similar to other membrane technology applications. However, there are key differences between reverse osmosis and filtration. The predominant removal mechanism in membrane filtration is straining, or size exclusion, so the process can theoretically achieve perfect exclusion of particles regardless of operational parameters such as influent pressure and concentration.

Reverse osmosis, however, involves a diffusive mechanism so that separation efficiency is dependent on solute concentration, pressure, and water flux rate. Reverse osmosis is most commonly known for its use in drinking water purification from seawater, removing the salt and other substances from the water molecules.

The efficiency of a reverse osmosis water filter is affected by the water pressure coming into the system and the temperature of that water. Membranes are tested at 65 psi of pressure and temperature of 77 degrees. For each incremental change in either variable, membrane performance changes accordingly. Higher pressures increase production and vice versa. The optimal pressure is 65 PSI and temperature is 77°, as seen here on our reverse osmosis pressure/temperature chart.

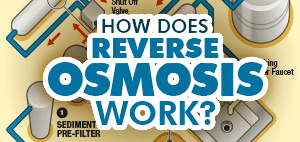

Stages in a Reverse Osmosis System

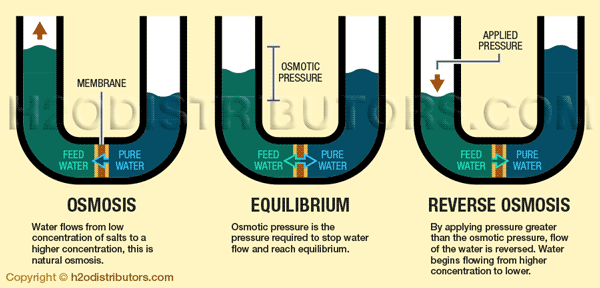

Below is a simplified and exploded diagram of a typical 4-stage reverse osmosis system. The stages have been numbered and the arrows show the directional flow of the water as it moves through the system. A larger diagram of the membrane is featured at the bottom to show its many layers, the component of the system that makes it a ‘reverse osmosis’ system.

1. Sediment Pre-Filter

Melt Blown Polypropylene removes dirt, rust and sediment particles down to 5 microns. There are several different types of sediment cartridges.

Pleated filters feature increased surface area and longer life. These cartridges are washable and reusable.

Melt blown polypropylene filters are designed for the removal of dirt, rust and sediment from water. 5 and 20 micron are the most popular sizes for drinking water applications.

String wound filters are an inexpensive solution to your filtration needs. These cartridges come in a variety of media types and have a wide range of applications.

2. Carbon Pre-Filter

Coconut Shell Carbon Block Cartridge(s), 10 Micron removes chlorine, taste, odor and chemical contaminants.

Activated carbon block filters typically have a 0.5 to 10 micron filtration capability, making it also helpful for particulate filtration, removing taste and odor from chlorine, insoluble lead reduction, and demonstrating, in some cases, removal of Giardia and Cryptosporidium. A 5-stage reverse osmosis system has an third housing to hold an additional carbon block cartridge.

3. Reverse Osmosis Membrane

Thin Film Composite (TFC) rejects (removes) 95% of Total Dissolved Solids (TDS) down to .0001 Microns.

Thin film composite membranes (TFC or TFM) are semi permeable membranes manufactured principally for use in water purification or water desalination systems. They also have use in chemical applications such as batteries and fuel cells.

4. Post Carbon Filter

Coconut Shell Activated Carbon is the final polishing filter after storage tank, just before you use the water.

Inline post filters typically clip onto the top of a reverse osmosis system’s membrane housing. The post filter removes any chlorine or contaminants missed by the other cartridges or membrane.

What Can Be Removed From Drinking Water?

The reverse osmosis process can remove a myriad of organic and inorganic contaminants from your tap water.

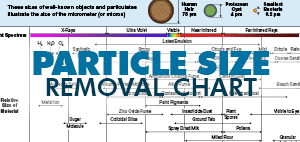

These systems specialize in removing chlorine taste and odor, rust, sediment and also alleviate common worries about public water by reducing or completely removing arsenic, asbestos, chromium, fluoride, lead, mercury, VOCs, THMs, giardia and cryptosporidium. For a more expansive list, view our contaminants removed by reverse osmosis list or our thin-film membrane particle size removal chart above.

What Makes Up a Reverse Osmosis System?

The following components make up your reverse osmosis system:

Reverse Osmosis Module

The RO module is the main component and holds the pre-filters and membrane, and post filter. A bracket is provided so they can be mounted under the sink or in a basement.Feed Water Valve (Angle Stop Adaptor)

Feed water valve connects to the cold water line to supply water to the RO system. This valve comes in several different types. An angle stop valve screws onto the cold waater line directly above the cold water shut-off valve. A faucet adaptor connects to the cold water line just below an existing faucet. A self-piercing valve clamps onto the cold water line and makes a small puncture in the pipe.Pre-filter #1

Melt Blown Polypropylene filter removes larger particles such as dirt, rust & sediment.Pre-filter #2 (And #3 If Applicable)

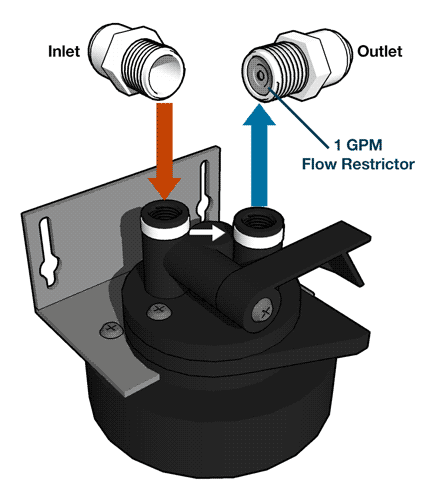

10 Micron Carbon Block removes chlorine and chemical contaminants in the feed water and protects the RO membrane.Automatic Shut-Off Valve

Automatic shut-off valve closes when the storage tank is full and shuts off the water supply to conserve water. The valve activates when the tank pressure is 2/3 of the feed pressure.Membrane

Reverse Osmosis Membrane Thin Film Composite Membranes reduces dissolved minerals, metals, and salts. In this process, harmful compounds are separated by the membrane from the water, and the contaminants are flushed to the drain.Drain Valve

Wastewater saddle valve connects to the drain to remove reject water from the RO system.Post Filter

A coconut shell activated carbon post filter is provided for a final “polish” and to remove tastes, odors and to provide great tasting water.Bladder Storage Tank

Bladder tank holds RO purified water, ready to use.Drinking Water Faucet

The RO Faucet is used to dispense purified water when you want it.Tubing

Tubing connects all RO components.Quick-Connect Fittings

Quick-Connect fittings are used for necessary tubing connections. See: Instructions for Quick-Connect Fittings.

Our Reverse Osmosis Systems