Installation Diagrams

Requires Adobe Acrobat Reader

Whole House Filters

Whole house filters are typically recommended to be installed by an experienced professional installer. This could be a WQA-Certified Installer, a plumber, handyman, or you can do-it-yourself if you have the knowledge of working with pipe & fittings.

Because we recommend a professional installation these instructions will not detail how to solder copper pipe or how to join plastic piping systems. These skills are considered prerequisites to a successful installation.

Our whole house systems use standard National Pipe Thread (NPT). The non-backwashing systems have female 3/4" or 1" NPT connections standard. The backwashing systems have male NPT fittings. 3/4" or 1" is available. Because of the use of standard pipe thread, the installation should be straight forward to a person with plumbing experience.

Whole House Filtration System Installation: How & Where

In a nutshell, the unit should go as close to the main water line as possible, after the pressure reduction valve, but before any T or splits. A small section of the pipe is removed. Elbows, adaptors, & pipe or fitted so that an inlet line feeds the water into the system & an outlet line connects it back to your existing plumbing.The main water line is usually located in a basement, crawl space, or garage. Sometimes it may be in a well house, laundry room, hot water closet, or possibly even under the stairs.

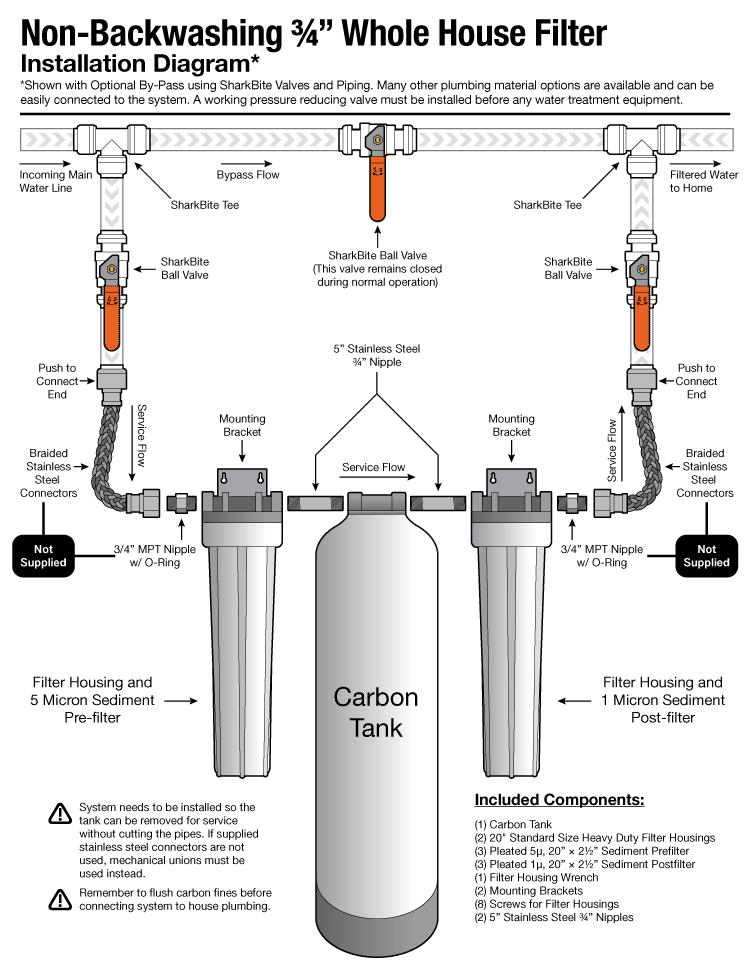

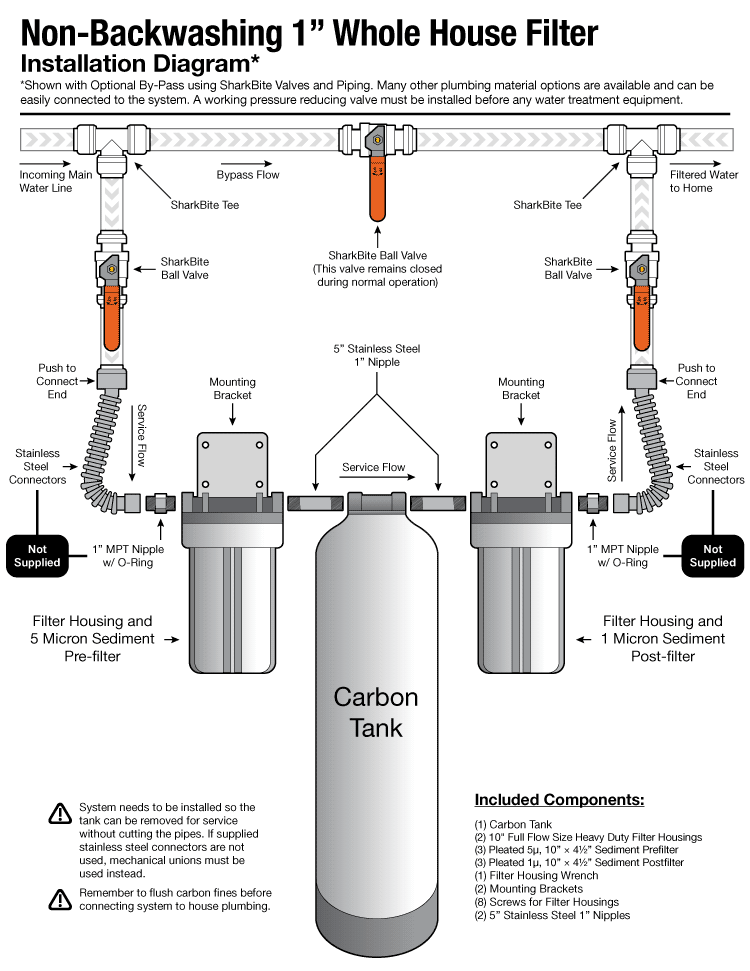

Non-Backwashing Systems

For your installation to be done the best way, replaceable cartridge housings should be firmly bracketed to a wall. These non backwashing systems should be installed with mechanical unions on each side of the tank to allow easy access for future maintenance. A pressure relief/flush port is another option to consider. This port makes flushing carbon dust and relieving pressure for filter changing much easier.A permanent bypass assembly is recommended for a premium installation. This bypass gives the ability to completely bypass the filtration system and use untreated water at any time. It also allows for easy removal of the system in case you want to take it with you. To build a bypass it takes 3 shut-off valves (we recommend using ball valves), 2 T’s, some pipe and some additional labor.

We usually do not recommend this permanent bypass on a backwashing system because it has a built-in bypass.

Automatic Backwashing Systems

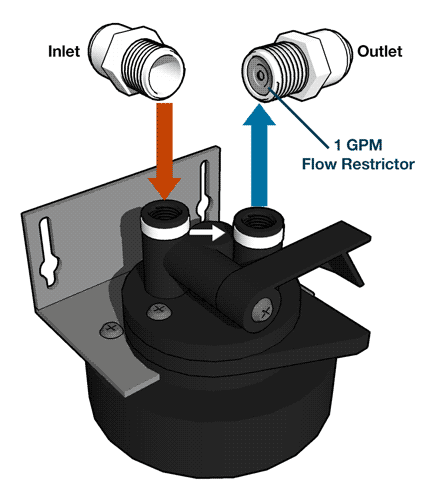

Installation of these systems requires the consideration of some drain water. When the system backwashes, it sends up to 5 gpm of water to the drain for about 10 minutes. This water can go into a laundry sink, floor drain, washing machine drain, or it can go outside on some bushes or grass. If none of these options are available, a P-trap and air gap drain assembly is recommended to make a connection to any existing drain pipe in the ceiling of a basement or garage. If no drain is available a non-backwashing system must be used.Electricity is required to run the timer and the backwashing control valve. A standard wall outlet is sufficient. The unit only uses about $2 in electricity p/year. If your system has an ultra-violet light component, it also needs an outlet.

Flushing the System

In many filters, the first water that comes out should be run to drain. This first water carries a residue or dust, often has an off color, and needs to be flushed out before connecting the unit to service. A minimum of 25 gallons should be flushed through. The remainder can be flushed through out the garden hose or though the pipes in the home.In a backwashing system, a backwash cycle can be initiated and this flushing process can be done automatically after the drain line has been connected. Simply plumb the unit in with the bypass valves closed and run the drain line. Turn on the water and check for leaks. Then initiate a backwashing cycle and then open the bypass valves. Allow the water will run to the drain for at least 10 minutes before putting the unit into service.

Professional Whole House Filtration System Installation

H2O is happy to provide assistance with installations by phone, free of charge. We have Certified Water Specialists on staff who have many years of field experience installing systems.